CNC Metal Machining

Get Online Quotes in 12 Hours

CNC Metal Machining

- The world’s only 12-hours injection molding quote

- Samples shipped in as little as 15 days

THE BEST BRANDS PUT THEIR TRUST IN JINTAI MOLD

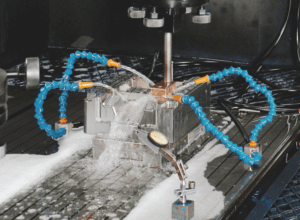

CNC Metal Machining

Jintai Mold offers a full range of Computer Numerical Control (CNC) metal machining services. Our metal milling services can be used to create part prototypes or small batch part runs. Jintai Mold is part of the Fathom manufacturing network with access to a wide range of CNC and injection molding machines. Speak with the experts at Jintai Mold to find out how we can save you time and money on your next project. Or try our online quoting system and receive an instant quote today.

CNC machining is a manufacturing process that uses high speed, computer-controlled, precision machines to remove plastic or metal from a blank block of material to create a part. The process is highly repeatable, resulting in the same identical part each and every time.

What Does CNC Stand For?

Computer Numerical Control (CNC) is a manufacturing process that utilizes computer controlled cutting tools. CNC machining is a subtractive manufacturing process. The cutting tools remove material from a blank block, leaving only the desired part behind. It is the same principle as a sculptor revealing the statue hidden in a block of marble. The CNC machine is controlled by Computer-Aided Manufacturing (CAM) software. Computer Aided Design (CAD) files are loaded into the CAM software. The CAD file acts as a set of directions, telling the CNC machine where and how to cut away material.

Can You Cut Metal with a CNC Machine?

Yes! CNC machines are mainly used to cut metal or plastic. CNC machining is ideal for manufacturing prototype parts and small part runs. There are several different types of CNC machines that can be used to cut metal. A CNC machining online quote is available through our instant online quoting system.

How CNC Metal Machining Works

Benefits of CNC Machining

Capability:

- Fast turnaround time for most custom CNC milled metal parts.

- Various surface finishes are available.

- Tight tolerances. Within +/- 0.002 in. (0.05 mm) for metal parts.

- No size limitations.

- Receive a CNC machining online quote instantly through our project portal.

CNC Metal Machining Services