Plastic Injection Mold

Injection molding is a manufacturing process used to make plastic parts. Plastic injection molding can be used for anything from manufacturing a few prototype parts up to running millions of an identical part. Plastic injection molding is ideal for making large quantities of the same part or related parts. Jintai Mold by Fathom provides custom plastic injection molding for customers worldwide.

Plastic injection molding has almost unlimited manufacturing possibilities. Examples of plastic injection molding can be found in a variety of industries including consumer electronics, car parts, medical devices, tools, toys, and packaging. Post-processing applications can be used to achieve the desired finish or texture. Plastic injection molding is an economical way to mass-produce the same or similar plastic parts.

The Basics of Plastic Injection Molding

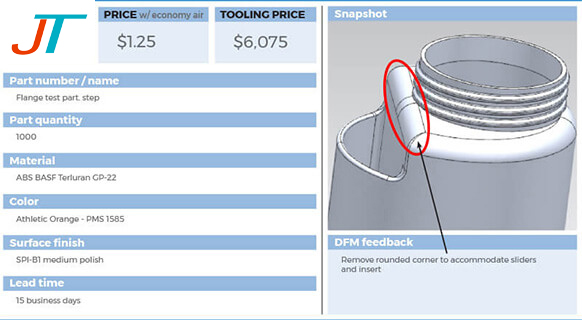

Cost of Plastic Injection Molding

What are the Disadvantages of Injection Molding?

Injection Molding Plastic

- Crystalline Plastics

- Amorphous Plastics

- Imidized Plastics

- Polyethylene (PE)

- Polypropylene (PP)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyoxymethylene (POM)

- Polystyrene (PS)

Plastic Injection Mold Services