Low-volume Injection

Get Online Quotes in 12 Hours

Low-volume Injection

- The world’s only 12-hours injection molding quote

- Samples shipped in as little as 15 days

THE BEST BRANDS PUT THEIR TRUST IN JINTAI MOLD

Low-volume Injection

CNC (Computer Numerical Control) Machining is a subtractive manufacturing process that involves using high speed, precision cutting tools to remove material from a blank block. The block is usually made of plastic or metal. The CNC machine carves away material from the block to create the part.

Benefits of CNC Machining

CNC Prototyping

A plastic prototype part ensures the product design is sound when starting a new plastic injection-molding project. For most plastic parts, a CNC machined prototype can provide exactly what is needed for testing purposes. CNC machining allows designers to test the form, fit, and function of parts that will be injection molded without the cost to produce the injection mold tooling.

Small Production Run

Plastic injection molding is the ideal process for making hundreds, thousands, or even millions of the same part but it is not cost effective for small runs. CNC plastic machining services are the perfect manufacturing process for making a small quantity of parts. All that is needed is the CAD file and a block of plastic. CNC machining can save customers a substantial amount of money during the prototyping phase or when making only a handful of parts. CNC plastic machining services do not require the time and money needed to produce an expensive mold. Parts can be created directly on the plastic CNC machine. It is the perfect manufacturing process for runs under 100 pieces. Part runs over 200 pieces may be produced cheaper with injection molding.

Quick Turnaround Time

Plastic CNC machining services are fast and efficient. The part can be cut almost immediately after receiving the CAD file. Other manufacturing processes like injection molding will take more time and effort to produce a single part. Plastic injection molding requires a larger upfront cost and many hours of milling to make the mold. CNC plastic machining services do not have any upfront costs and can enter production quickly.

High Quality Parts

CNC plastic machining services have many advantages over manual manufacturing. CNC machining is a more precise process than manual machining and provides exact repeatability. Computer control ensure the machine movement and makes the tools move precisely and simultaneously on their axes to create complex, three-dimensional shapes that would be almost impossible with manual machining.

This accuracy and control makes CNC machining an ideal manufacturing process for jobs that require a high level of precision or repetition. Jintai Mold can hold all tolerances to within +/- 0.2 mm to 0.3 mm. Customers can specify tolerances up to 0.01 in. (0.254 mm) if there are critical areas on the part where tight tolerances are extremely important.

CNC machining can produce more robust parts in plastic then compared to 3D printing. CNC plastic machining services can be done on a wide range of plastic material. In many cases, the same plastic that will eventually be used for injection molding the final part run can be used for CNC machining prototype parts. These parts can then be subjected to the same tests and conditions as the eventual injection molded production parts.

Plastic CNC Machining vs. Plastic 3D Printing

What is the best plastic to CNC?

Types of CNC Machines

There are several types of CNC machines, each with its own functionality to machine different types of parts in different ways.

CNC Mills

CNC mills generally start with a black block of material that removes excess material until only the desired part is left. The CAD file is translated into G-code (or similar code). This code is then uploaded to the CNC mill, where the computer controls the spindle in a three-axis system (X, Y and Z). The code contains the coordinates for the part and the speed at which the spindle should spin. The CNC mill follows the code in order to create parts from plastic or metal.

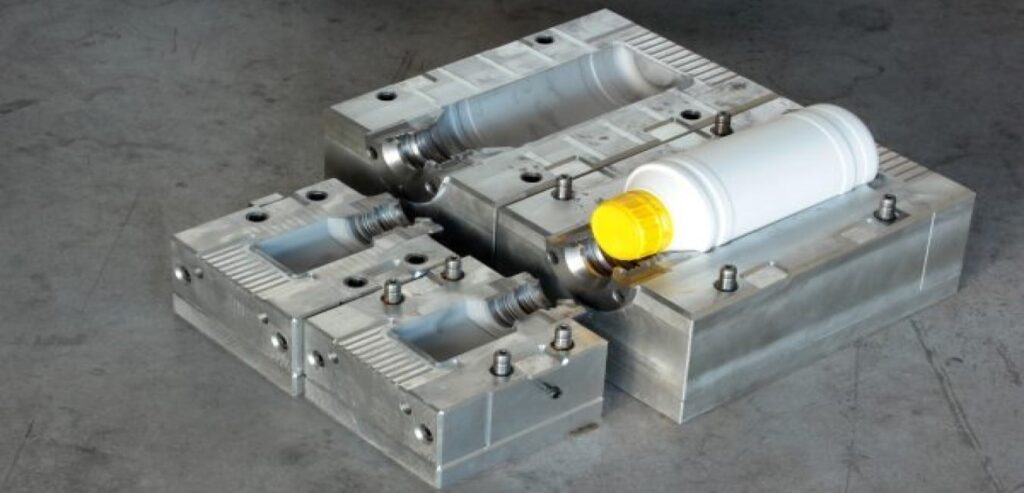

CNC Lathes

CNC lathes differ from CNC mills as they only move their spindles in a two-axis system (X and Y). CNC lathes take a blank and then spin it at a high RPM. Any cuts made to the blank are uniform on all sides. CNC lathes are used for creating cylindrical pieces that need to have uniform cuts on all sides.

CNC Plasma Cutters

CNC plasma cutters use the same technology as other CNC machines. CNC Plasma cutters are used for cutting parts out of large, flat metal sheets instead of a block of metal. Plasma cutters, like lathes, can only move their tool tip along two axes.