Pressure Die Casting

Get Online Quotes in 12 Hours

Pressure Die Casting

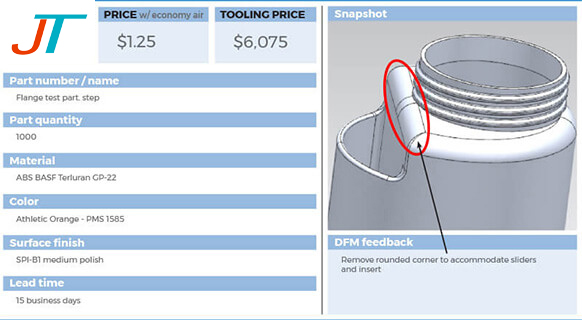

- The world’s only 12-hours injection molding quote

- Samples shipped in as little as 15 days

Low-Cost Injection Molding Leader

THE BEST BRANDS PUT THEIR TRUST IN JINTAI MOLD

Pressure Die Casting

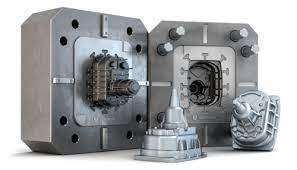

Experience the versatility of high precision die casting with Jintai Mold. Our pressure die casting services offer consistent excellence, catering to both small and large volume production needs. Perfect for industries like automotive, electric, aerospace, kitchenware, and hardware applications.

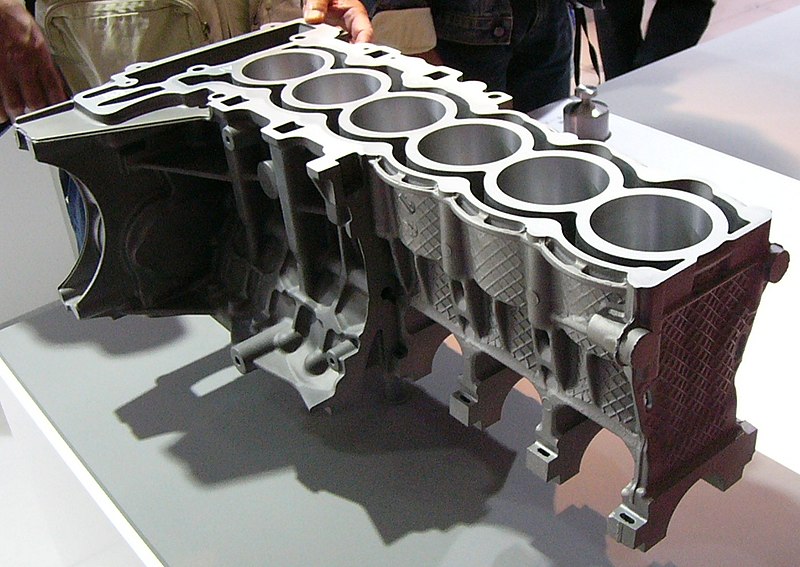

What is Pressure Die Casting?

Pressure die casting, also known as die casting, is a method used for producing intricate parts from non-ferrous metals such as aluminum, zinc, and magnesium. Molten metal is injected into a reusable steel mold, or die, under high pressure and speed, resulting in finely detailed components with exceptional surface finish.

Die Casting Materials:

Explore various materials tailored to your specific requirements:

- Aluminum Die Casting: Utilizing lightweight aluminum alloys like A356.0, A360.0, A380.0, A383.0 (ADC12), A413.0.

- Zinc Die Casting: Versatile and high-performance zinc for parts with intricate details.

- Magnesium Die Casting: Ideal for complex castings with enhanced corrosion resistance.

Available Finishes:

Select from a range of finishes to meet your aesthetic and functional needs:

- Standard (As-Cast)

- Bead Blasted

- Anodized (Type II Or Type III)

- Powder Coating

- Wet Painting

- Plating

- Chemical Film

- Media Tumbled

- Custom

Benefits:

Experience the advantages of pressure die casting:

- High-volume production with precise accuracy

- Cost-effective solution for mass production

- Rapid solidification of molten metal for faster production cycles

- Ability to produce thousands or even millions of components before replacement

- Suitable for a wide array of applications, especially complex and precise components

- Close dimensional control and superior surface finish

- Lightweight components with thin walls

- Electroplating compatibility without additional processing

For more information on our pressure die casting services, contact us today.