Rapid Prototyping

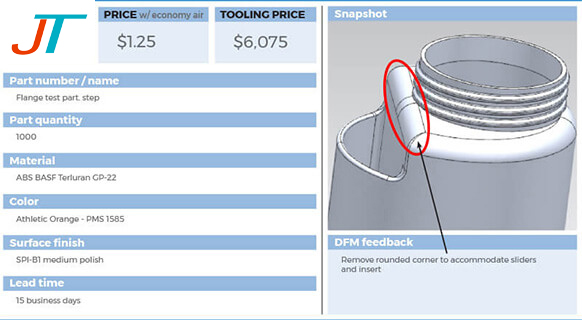

Get Online Quotes in 12 Hours

Rapid Prototyping

- The world’s only 12-hours injection molding quote

- Samples shipped in as little as 15 days

THE BEST BRANDS PUT THEIR TRUST IN JINTAI MOLD

Rapid Prototyping

For prototype quantities of custom metal and plastic parts, CNC Machining is often the best process, short of tooling, to match proposed production-part properties. We take your 3D CAD model and create precision CNC (Computer Numerically Controlled) machining paths that guide our equipment to follow every contour and hole. The result is a precisely replicated part, exactly matching your original design.

You should choose Rapid CNC whenever you require parts in the exact material you plan on using in production. Other rapid prototype processes can often simulate the final material, but we know there are times when substitution is just not an option.

Choosing Between Rapid Prototyping Processes

Rapid CNC Machining

Rapid Sheet Metal Fabrication

Rapid Injection Molding

Why Choose Rapid Prototype Service?

Endless Options

Choose from thousands of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.