Export Injection Molds

Jintai Mold offers full production injection molds that will be exported from our wholly-owned manufacturing plant in China, for you to run in your own facilities or at a manufacturing facility that you designate. A mold for plastic will be designed and built according to the USA/Western standard. It will be optimized for production on your injection molding machine with details such as cooling line connections already prepared for your existing setup.

Different customers have different tooling requirements, so we can build to your plastic mold injection system specifications, including the steel, hot runner system, processes, surface polish or texture of the injection mold plastic. We can also take your functional requirements for the molds and injection molding and match the production specifications and mold designs. Pilot and short production runs are available upon mold completion, such as for bridging a production tooling gap.

Quality Matters, and Not All Mold Makers Are the Same

Mold Durability

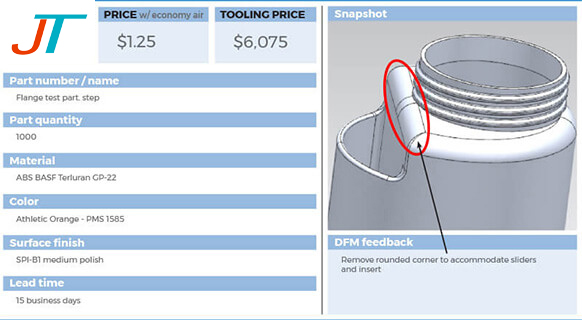

Make Sure Your Injection Molds are Properly Designed

Process for Export Injection Mold

- Load your 3D CAD file to get the injection mold tooling quote

- Upon order confirmation, Jintai Mold starts the export mold order process

- You will receive the 3D full mold design for review and approval

- Upon design approval, Jintai Mold begins building the injection mold

- Sample approval and pilot production

- Tooling delivery