Family Molds

Custom Plastic Injection Molding is used to make custom plastic parts. Customers in need of large production runs or production runs of related parts can save time and money but utilizing family molds or multi-cavity molds.

Family mold injection molding and multi-cavity injection molding are similar processes used to produce a set of parts that are molded at the same time. All of the parts will be similar in size, in the same color and quantities, and made from the same material.

Plastic injection molds are made of metal and used to create custom plastic parts. A cavity is machined into two blocks of steel. The steel mold is placed in the plastic injection machine and held closed under pressure. Molten plastic is then forced into the mold. The mold opens after the plastic cools and the part is ejected before the process starts over.

What Are The Benefits of Family Molds

Lower Tooling Cost

One family mold can be created with multiple cavities instead of creating multiple, single-cavity injection molds and paying the tooling cost for each one. Tooling costs are dramatically lowered by only machining one mold.

Lower Production Cost

Family molds and multi-cavity molds will reduce production costs. Production time is lowered since there is no need to switch out molds. Multiples of the same part can be created each time the mold opens. The per-piece price of each part will go down if multiple parts are produced each time the mold opens.

Easier Ordering

Family injection molds can make it easier to place orders. If a product requires a left side and a right, those parts can be machined into one family mold. The customer only has to order from that mold instead of multiple molds. This also ensures the correct amounts of parts are sent to create the finished product.

Scalability

Making one million parts with a single cavity mold would tie up machines and resources for weeks or even months depending on the length of each injection cycle. A multi-cavity mold can substantially reduce production costs and turnaround time.

Required Criteria for Family Injection Molds

All parts produced in a family injection molds or multi-cavity injection molds will be the same material and color. Only one type of material can be sent into the mold at any given time. Since there are multiple cavities in the mold, all cavities will be filled with the same material. Parts that need to be different colors or made of different materials cannot go into the same family mold.

This is not really a requirement but something to keep in mind when creating family molds. Every time the mold opens, the exact number of parts in the mold will come out. If the mold produces Side A and Side B to make one complete product, then each time the mold opens it will produce enough parts to complete one product. If the mold produces one of Side A and two of Side B, the customer will end up with one extra Side B every time the mold opens. This is only a detriment if there are parts left over. Family molds do not need to adhere to a 1:1 ratio. If the final product requires one of Side A and two of Side B, then utilizing a family mold will save the customer time and money.

Process for Family Injection Mold

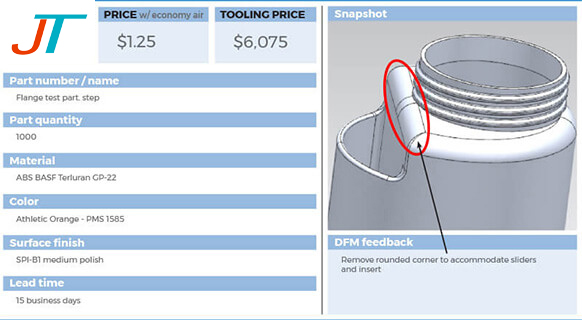

- Upload the 3D CAD file to get a quote for mold and part cost.

- Jintai Mold starts the mold and part order process upon order confirmation.

- Jintai Mold engineers review the tooling design.

- Jintai Mold begins building the injection mold after design approval.

- Customer examines samples for approval.

- Part enters production.

Family Molds Services