Production Molds

Production injection molds are built to withstand higher volumes of plastic injection molding cycles. They are made with P20 steel or NK80 stainless steel, and typically last over 100,000 cycles. As long as we continue to make your parts in our facility, we will maintain and repair the tool as needed at our cost.

Yes, making design changes on production molds is possible with Jintai Mold. An Jintai Mold engineer will coordinate with you on CAD file changes and rework the mold accordingly. You will receive revised samples for your approval prior to production.

Advantages of Production Injection Molds

Less Wasted Material

On average, even with the extra connection pieces (runner), injection molding produces less wasted materials than CNC machining. This is because CNC machining starts with a solid block of material and then the part is cut out from the block. On very small production runs this cost maybe negligible. On larger production runs, and with more expensive material, this waste can add up to significant cost.

Less Production Time

CNC machining doesn’t require any upfront tooling. Once a CAD file has been finalized, it can be sent to production. CNC machining shines when there is a small production run. Once you get to a certain amount of parts in a run (this is determined by part size and complexity), it becomes quicker to produce parts with injection molding.

The biggest time sink for plastic injection molding is the creation of the production mold. Once the production mold has been created and properly set up, it takes only a few seconds to produce a part. The larger quantity of parts in a production run, the larger the time savings over CNC machining.

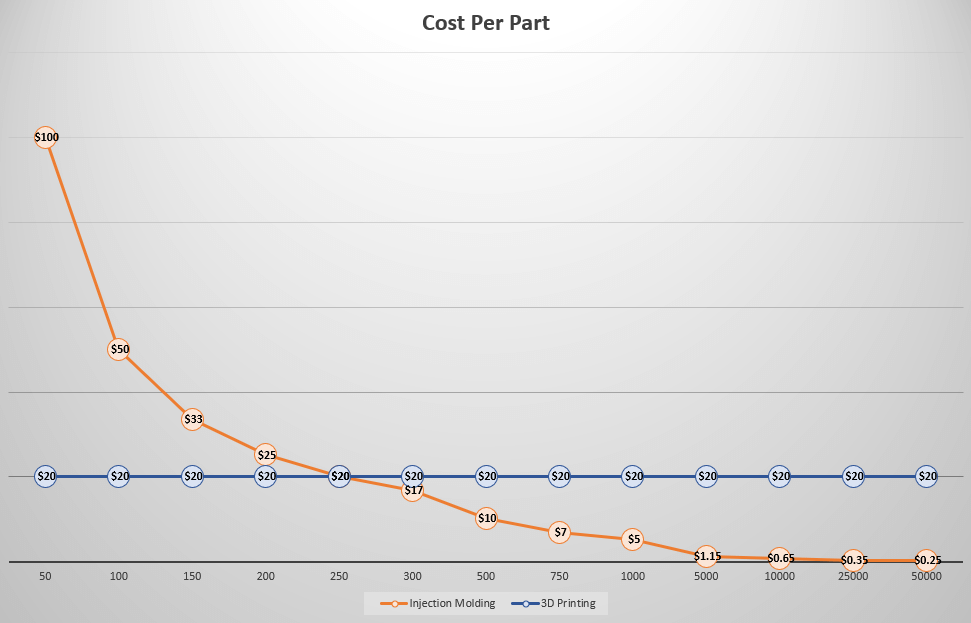

Lower Cost On Higher Production Runs

For CNC machines, each part has to be manually placed in and removed from the machine, so the cost per part is fairly static over production runs. For plastic injection molding, the production mold is by far the most expensive item. After the mold is created, the parts are fairly inexpensive and fast to produce. Since plastic injection molding is fast and doesn’t require human interaction once the production mold has been setup, the cost per piece decreases as quantity increases. Depending on the complexity of the part, it can be cheaper to use plastic injection molding for as few as a couple hundred parts.

How long does a plastic injection mold last?

These custom plastic injection molds will typically last well over 100,000 cycles. As long as we continue to make the parts for you, we will maintain and refurbish the tool as needed at our own cost.

Making design changes on production molds is possible with Jintai Mold. An Jintai Mold engineer will coordinate with you on CAD file changes and rework the mold accordingly. You will receive revised samples for your approval prior to production.

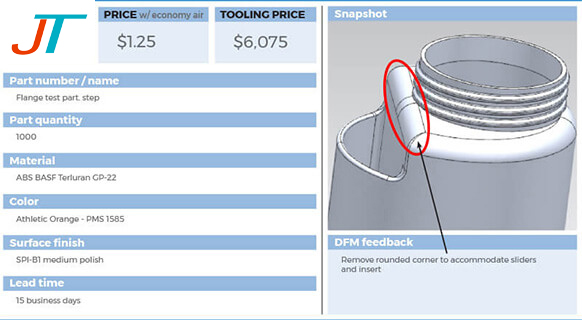

Injection Molding Production Highlights

> Instant mold and part quote

> Low cost, quick build and quality production

> Online project management

> Trouble-free part modifications

> No size limitations

> Any commercially available material and surface finish

Production Molds Services